Custom slip rings

The function of a slip ring is to make one or more continuous electrical connections from points in a stationary unit to points in a rotating section.

Pancake slip rings

Pancake or “platter” type slip rings are in a flat disk form with concentric conductor rings to provide a maximum number of conductor rings with a minimum amount of axial length.

Slip ring configurations

Sibley can manufacture a wide variety of slip ring configurations to meet your specific needs.

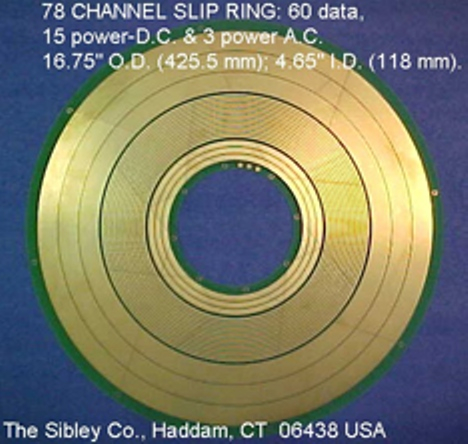

Complex Electrical slip rings

Electrical slip rings can combine a large number of data & power channels for rotating applications in research, satellite tracking and other complex equipment.

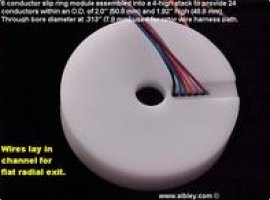

Through bore slip rings

Through bore slip rings have a center hole to provide clearance for shafts, rotary joints, optics and other axial structures.

Split construction slip rings

Split construction slip rings can be sectional for assembly around a shaft that is in place or otherwise not possible to remove. This type of slip ring is ideal for printing presses, paper processing machinery or any other machines where shaft disassembly is not practical.

Large slip rings

Large size slip rings for high current or large physical size can be provided to meet the requirements for large equipment or other specialty applications.

Self-contained slip rings

Self contained disk type slip rings provide very low stack height and a through bore for use with center shafts, rotary joints, optics and any other axial assembly.

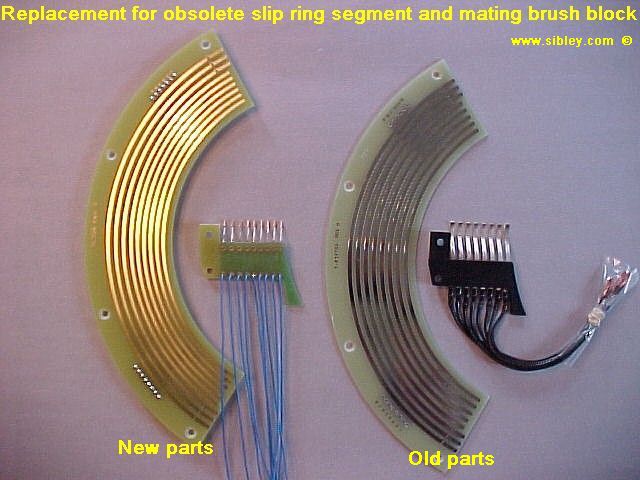

Replacement slip ring parts

Replacement parts for disk or “platter” type slip rings can be supplied when replacement parts are no longer available from the equipment manufacturer.

Retrofit slip rings

Slip rings for retrofitting to existing equipment are custom designed and manufactured to meet the exact form, fit and function needed.

Slip ring mounting options

Slip rings are designed to be installed and mounted in a variety of ways.

Slip ring connector options

There are a wide variety of options for slip ring connections.